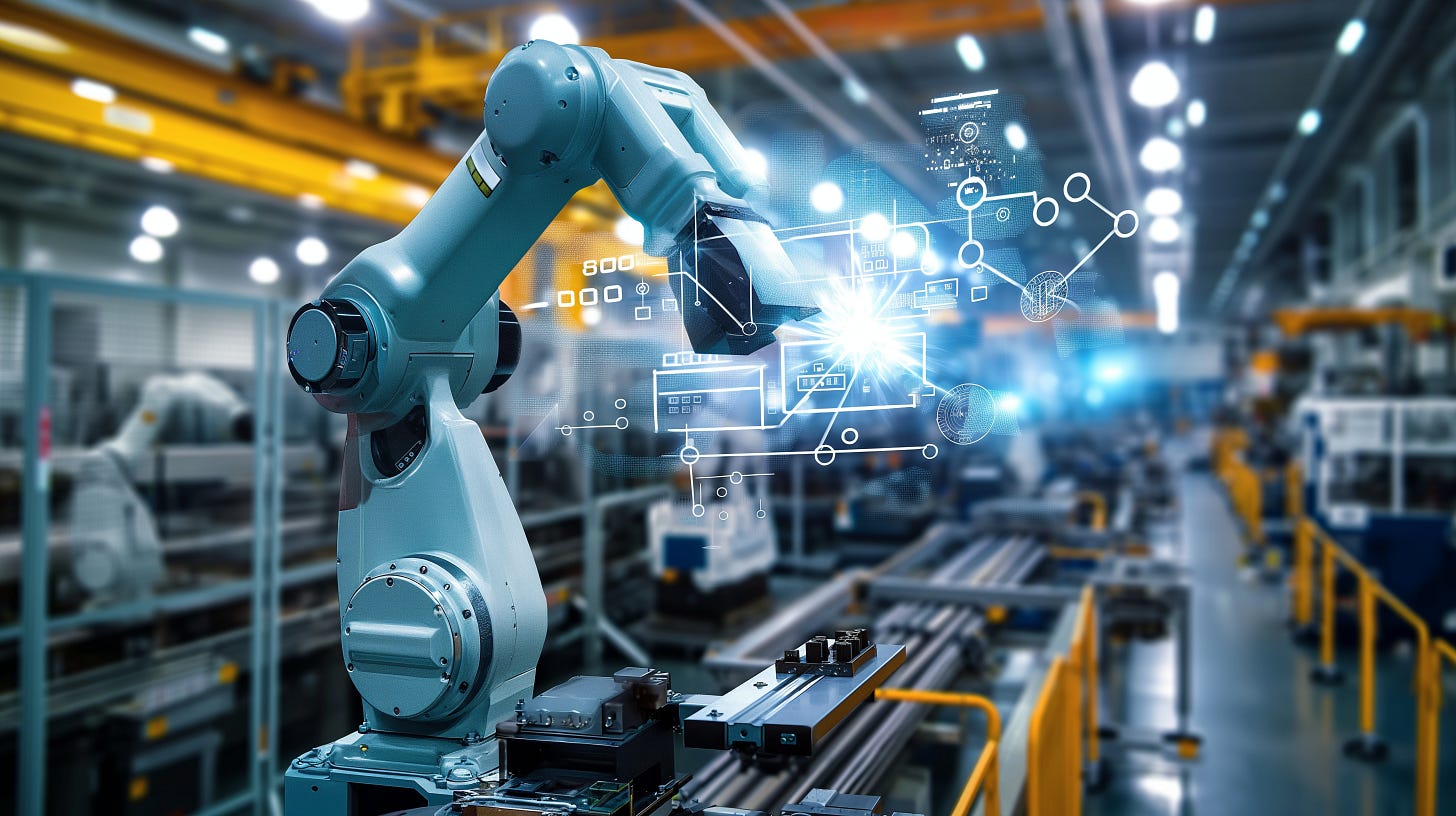

The factory floor is getting a high-tech upgrade, and it's not just about flashy robots. Artificial intelligence (AI) is quietly revolutionizing manufacturing, making processes smarter, more efficient, and more reliable than ever before. Here is how AI is driving change:

Optimizing Everything: AI algorithms can analyze enormous amounts of production data to find patterns unseen by humans. This means manufacturers can pinpoint inefficiencies, optimize machine settings, and streamline workflows, maximizing output and minimizing waste.

Predicting the Future (of Machines): Imagine knowing when a piece of equipment is about to fail, days or even weeks in advance. That's predictive maintenance made possible by AI. By monitoring sensors and historical data, AI models can spot anomalies that indicate an upcoming problem, allowing for preemptive repairs. This avoids costly downtime and keeps production lines humming.

Quality Control Gets an Upgrade: No more spot checks! AI-powered cameras and sensors can scrutinize products in real-time with tireless precision. From spotting microscopic defects to identifying mislabeled items, AI is ensuring only top-quality products leave the factory floor, leading to increased customer satisfaction and reduced waste.

The Big Picture

AI in manufacturing isn't science fiction; it's happening right now. The benefits are tangible:

Cost Reduction: Fewer breakdowns, less waste, and optimized operations all save money.

Increased Product Quality: AI-driven quality control boosts customer satisfaction and brand reputation.

Enhanced Agility: AI lets manufacturers adapt quickly to market changes and personalize products on demand.

The Future is Smart

The integration of AI into manufacturing is only accelerating. Expect to see AI-powered supply chain management, autonomous robots integrated with production lines, and even AI-assisted product design.

Let us know your thoughts in the comments!